|

Dry-mixed mortar is hydraulic mixed mortar, a kind of new building material, and refers to material with particle or powder shape, is transported to construction site by bag or in bulk, and can be used directly adding water to mix. It is formed by physical mixing of aggregate (for example, quartz sand) after drying and sieving treatment, inorganic cementing material (for example, cement and gypsum) and additive (for example, polymer) by certain ratio. According to performance, it can be divided into normal premixing mortar and special mortar. Dry-mixed mortar plays the function of adhesion, backing, protection and decoration in building industry by thin layer, and has very wide application in building and decoration works. It has health, environmental protection , stable quality, energy saving, comfortableness, etc.

Production line features:

1. Raw material drying uses three-cylinder drying system, discharge temperature ≤65℃, water content <0.5%;

2. Dust collection uses two-level or three-level dust collection system, pulses ash cleaning is controlled intellectually, and environmental protection discharge <30 mg/Nm3;

3. Efficient and stable proability sieve has efficiency over 87%;

4. Perfect computer control system ensures the whole production process is accurate and stable;

5. Advanced mixer uses variable frequency mixing technology, has high efficiency, energy saving, mixing ratio over 1:10,000, high wearing resistance and long life;

One production line can produce several types, including products such as dry mixed inner wall blocking mortar, dry mixed inner wall plastering mortar, dry mixed outer wall plastering mortar and dry mixed glazed hollow bead light mortar.

Flow chart:

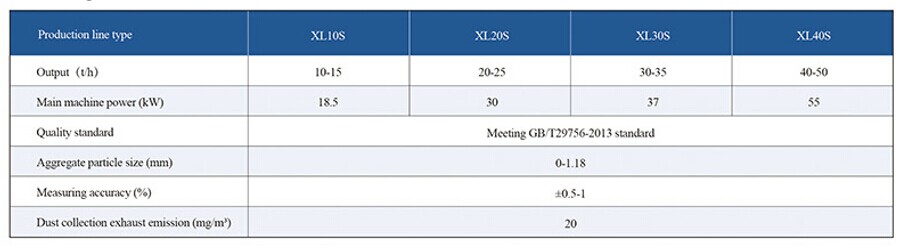

Technical index

|

> Product display >Production line

> Product display >Production line