|

Calcium based desulfurizer has the most popular application in desulphurization. Normal calcium based desulfurizer includes lime, slaked lime, carbide slag, limestone, dolomite, etc. Calcium based desulfurizer has wide source, easy and cheap raw material and high desulphurization efficiency. Limestone has rich reserve in the nature, and is main element is CaCO3. Limestone has large reserve in our country and high ore grade, and its CaCO3 content is normally over 93%. When using as desulphurization desulfurizer, limestone shall be ground into powder. Limestone hasn’t toxicity or harm, is very safe during handling and use, and is the first choice of dry process and wet process desulfurizer in domestic fluidized bed burning.

Production line features:

1. Civil work and equipment support use steel structure, which is short construction period, less investment and small floor area;

2. Crushing, grinding, feeding, dust collection, packing and bulk systems use optimal design, and technological indexes of systems are rational, as well as the whole production line has high output;

3. Production line uses perfect DCS computer control system, which ensures the whole production process is accurate and stable; key positions use video monitoring, and saves labor;

4. Dust collection uses two-level dust collection system, pulses ash cleaning is controlled intellectually, and environmental protection discharge <30 mg/Nm3;

5. Equip perfect test system, and ensure product quality meets the requirements.

Flow chart:

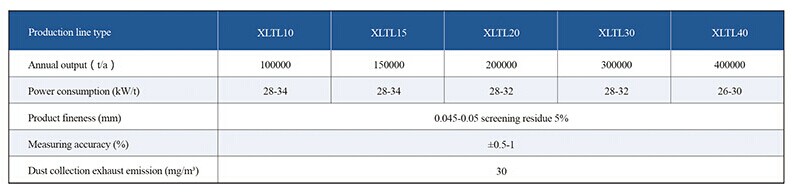

Technical index

|

> Product display >Production line

> Product display >Production line