|

Natural dihydrate gypsum (CaSO4.2H2O) is green natural source with wide application, nonrenewable and recyclable utilization. Building gypsum (β-CaSO4.0.5H2O) produced by natural dihydrate gypsum can produce and manufacture gypsum series new gypsum building materials such as gypsum plaster board, painting gypsum, plastering gypsum, gypsum dry-mixed mortar, gypsum slat, gypsum block, self leveling gypsum mortar and gypsum decoration product. In traditional three cementing materials, production energy consumption of gypsum is only 1/4 of cement production and 1/3 of lime, and gypsum is the present most popular building and decoration material.

Natural gypsum powder is produced from dihydrate gypsum (CaSO4.2H2O) by crushing, grinding, calcination, cooling equalization, aging and packing; core technology of gypsum powder production is calcination (dehydration) system, crystal structure of dihydrate gypsum, diversity of component and reactivity, which causes aquation and hardening diversity during producing finished product. Xianluo makes technical breakthrough on various systems, relies on research, development and production experiences for over 10 years, aiming at foreign and domestic new technology, new material and new product, develops series natural stone powder production line with energy saving, environmental protection and high efficiency successfully, and has built scores of modern natural gypsum powder production lines at home and aboard, whose excellence rate reaches 100%.

Production line features:

1. Civil work and equipment support adopted steel structure type, has various features such as short construction period, less investment and small floor area, and saves over 60% of fund than traditional civil works; construction period of production line with annual output below 100,000 tons is 75 working days;

2. The company has fine calcination, cooling equalization, gasifying and aging patent technology, adopting customized design according to raw materials at different areas and performances of later products and saves over 20% of energy, and energy saving equipment power consumption saves 15-20%;

3. Production line uses DCS automatic control technology, has high automatic degree and stable quality, and saves labor;

4. The whole line makes negative pressure operation, dust collection uses three-level dust collection system, tail discharge after treatment <30 mg/m3, environmental protection meets environmental protection standard in various areas;

5. Non-standard production guarantees equipment quality of the whole production line, perfect antisepsis and heat preservation measures; single equipment technical specifications are optimized, and each equipment used by production line meets features of gypsum production;

6. The company has specialized installation, training and adjustment team; the whole line has short installation period, by using unique production line calcination “0” adjustment expense to saves large investment to new enterprise.

Flow chart:

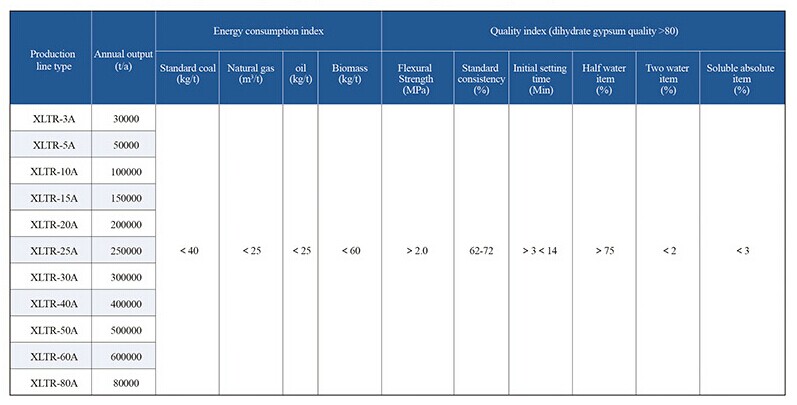

Technical index

|

> Product display >Production line

> Product display >Production line