|

α desulphurization high strength gypsum is powder cementing material with α type hemihydrate calcium sulfate as main crystal shape, which is obtained by placing dihydrate desulphurization gypsum in liquid water solution under certain temperature, pressure or crystal modifier condition. When hydrothermal process is used for producing α hemihydrate gypsum, mix dihydrate gypsum and water according to certain ratio, place them in high pressure kettle, add suitable quantity of crystal modifier, increase temperature to required temperature, after high temperature and high pressure heat treatment for certain time, dihydrate gypsum is converted into α type hemihydrate gypsum, after dehydration, drying and grinding, α type hemihydrate gypsum powder can be obtained.

Production line features:

1. The company has pilot trial production line, making analysis, test, small-scale test and pilot trial firstly, then determines production technology, ensuring one-time trial production success of production line and saving large adjustment expense;

2. Material proportioning, steam temperature, pressure and time, dehydration effect, drying degree and grinding time are all finished by DCS industrial computer automatically, which saves labor cost while guaranteeing product quality stability;

3. Multiple-heat source use: Able to use coal, gas, oil and biomass heat conduction oil burning boiler system, and able to use superheated steam to make heating and drying; whole heat preservation saves energy;

4. Civil work and equipment support use steel structure type, has various features such as short construction period, less investment and small floor area, and saves over 60% of fund than traditional multi-layer frame structure civil works.

Flow chart:

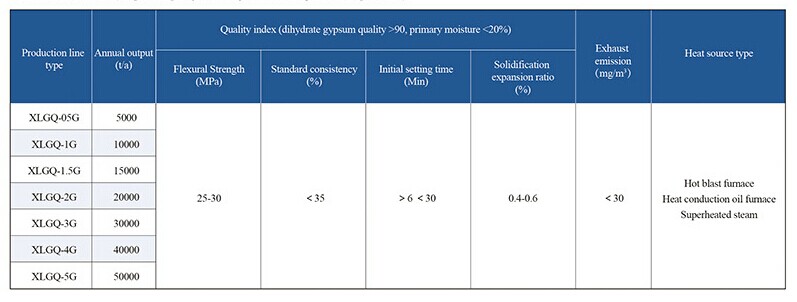

Technical index

|

> Product display >Production line

> Product display >Production line